B1 Fire-Resistance Aluminum Composite Panel

B1 Fire-Resistance Aluminum Composite Panel

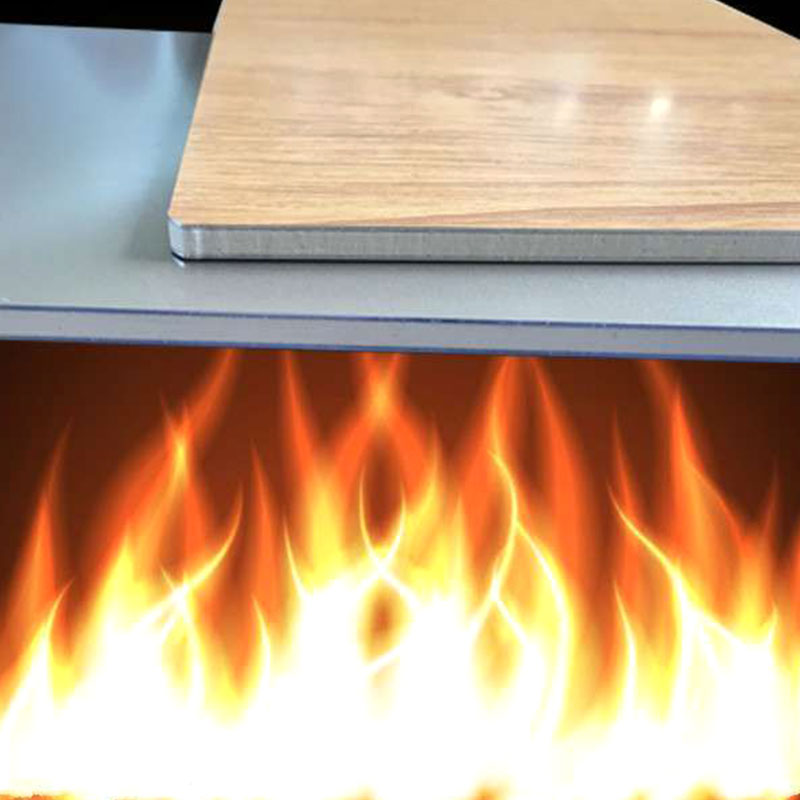

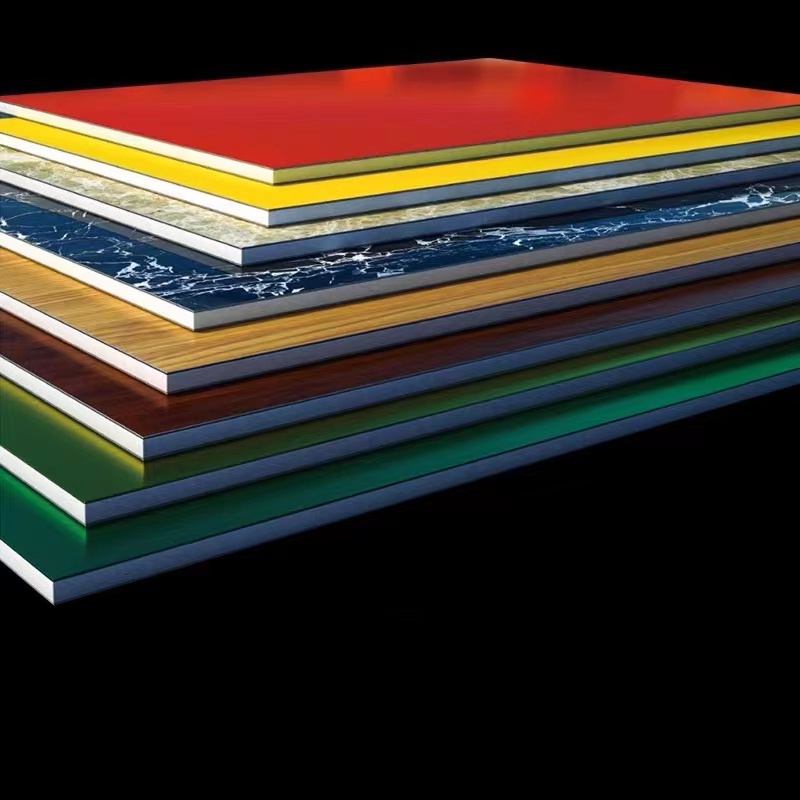

It is a sandwich panel which consisted of two sheets of aluminum bonded to a mineral filled fire retardant core. The FR B1 core is a mixture of fire retardant materials mixed with LDPE materials. The fire retardant material is majorly Mg(OH)2 or Al(OH)3, under heat it will react with oxygen and during this process it will absorb heat & release H2O which will greatly slow down the fire from spreading, and more importantly it won't release toxic black smoke compared with the flammable material ones. So for buildings that take FR B1 ACP as decorative materials, in case of fire accident, the fire retardant property helps to give more time for people inside the building to evacuating and reduce the casualty and loss to the minimum. The surface of FR B1 ACP is same like normal ACP, that is finished with PVDF, FEVE, PE or Anodize coating. In recent 10 years, quite a lot of big fires worldwide were pointing to the reason of using flammable decorative materials, thus it's very meaningful to use FR materials.

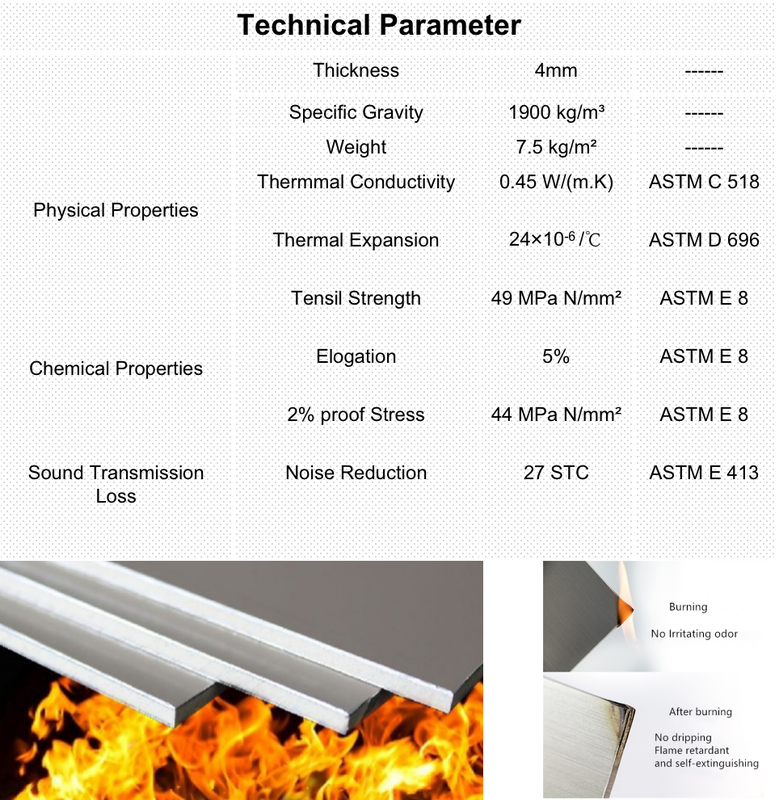

Product Specifications

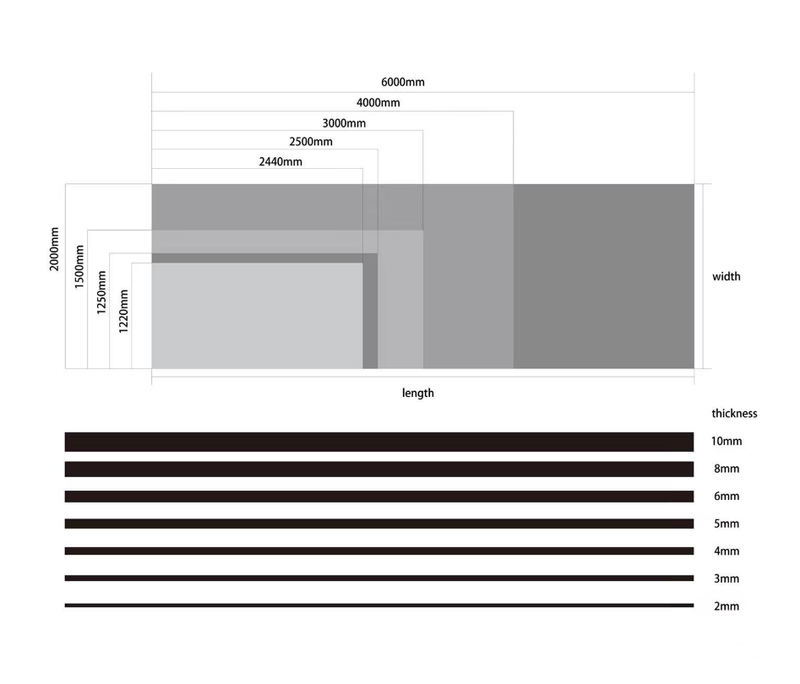

Thickness: 2-6mm; 3mm and 4mm is recommended

Width: 1000-2000mm; 1220mm, 1250mm and 1500mm are recommended

Length: Maximum is up to 5800mm, 2440mm,3000mm and 4000mm are recommended

Thickness of aluminum sheet: 0.21mm-0.5mm

Raw Material

Aluminum Material: High strength aluminum alloy sheet

Core Material: Fire-resist core ( B1 )

Surface Coating: PVDF, FEVE, Nano or PE coating

Bottom Coating: Anticorrosive primer coating

Characteristic of B1 Fire-resist ACP