PE Coating Aluminum Composite Panel

PE Coating Aluminum Composite Panel

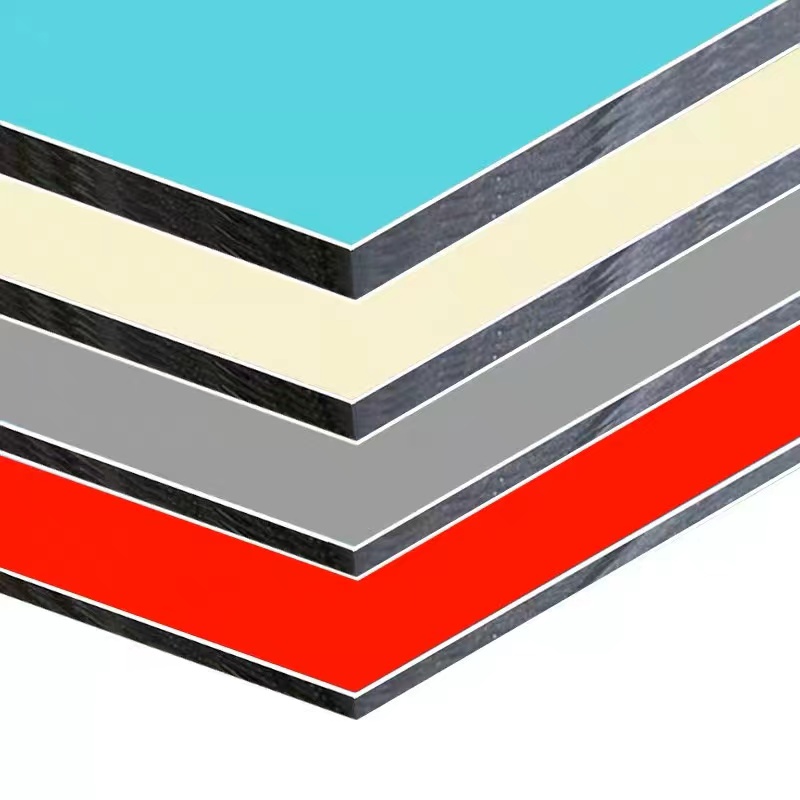

PE coating Aluminum Composite Panel has the two major types: matte and glossy. The monomer of the backbone chain is the high molecular polymer of the ester bond, which added the alkyd resin and ultraviolet absorbent. It is widely used in interior decoration and advertising board field. The structure of the polyester molecule is compact with the excellent surface which fully satisfy the high demand for surface flatness in printing and decoration. The life span for PE coating ACP is around 8-10 years.

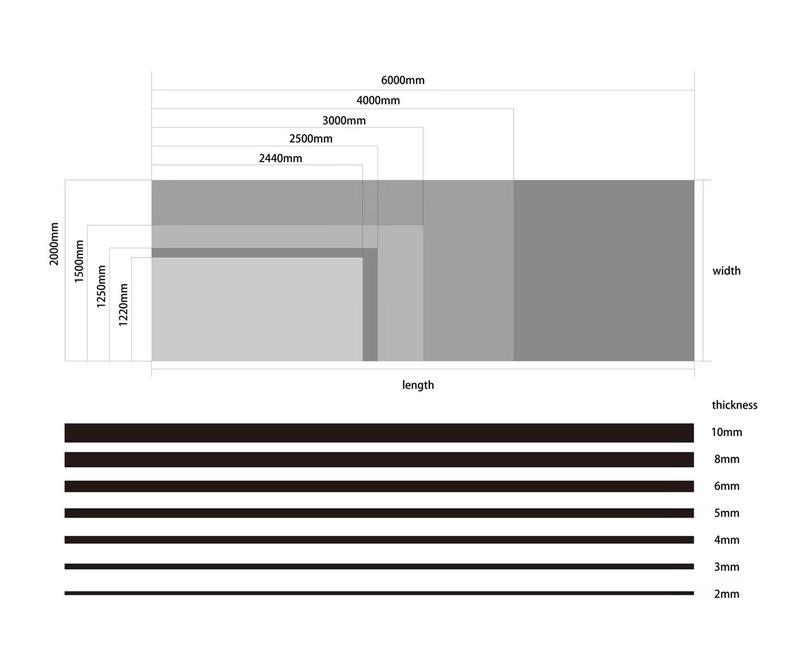

Product Specifications

Thickness: 2-6mm; 3mm and 4mm is recommended

Width: 1000-2000mm; 1220mm, 1250mm and 1500mm are recommended

Length: Maximum can up to 5800mm, 2440mm,3000mm and 4000mm are recommended

Thickness of aluminum sheet: 0.06-0.5mm

Raw Material

Base material of aluminum panel: high strength aluminum coils

PE core: non-toxic low density polyethylene

Surface coating: Polyester Coating

Characteristic of ALUCOBANG Panel

High dimensional stability

As a material, the composite panel does not present deformations in its dimensioning, which means that the material remains stable whatever its size without losing its properties

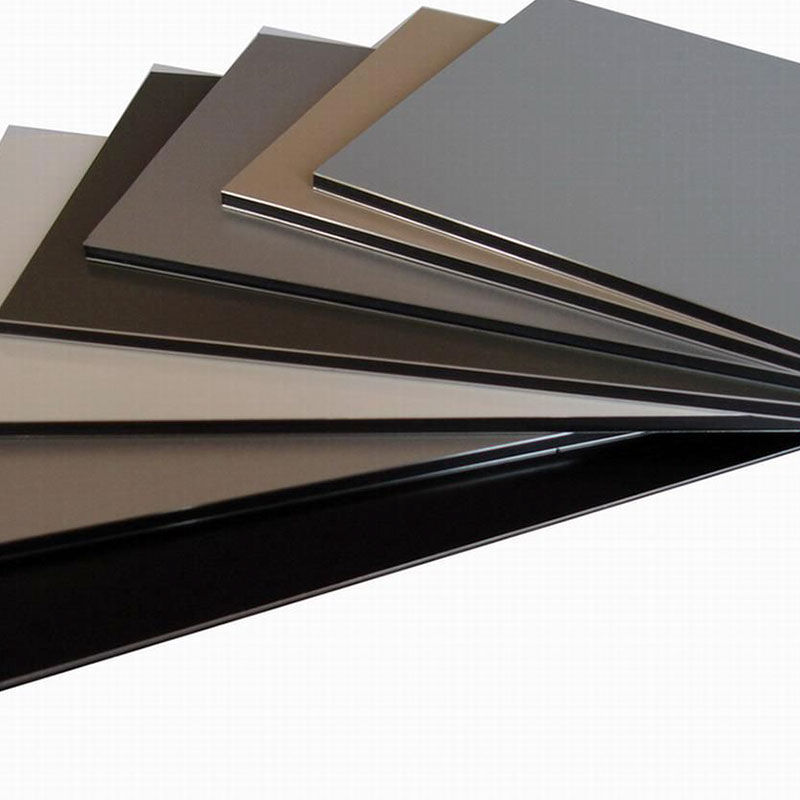

A multitude of finishes

The wide range of finishes that the composite panel allows gives it a great aesthetic versatility. From solid to textured, mirror or wood type finishes, the composite panel can be adapted to almost any type of project

Impact resistant

Recent studies confirm the durability of aluminium in building facades due to its long life and resistance to wear and corrosion

Fully recyclable

The core material and cover sheets of aluminum composite panel can be recycled and reused. Due to its characteristics, aluminium can be recycled indefinitely

Quick and easy assembly

The hanging systems for the assembly of aluminium composite panels are designed to facilitate their assembly on facades in a quick and easy way. In the same way, in case that a cassette is damaged, it can be easily replaceable

Light as a feather

The low density of aluminium makes it the ideal material for substructure systems on ventilated facades