1500*5850mm 4mm PVDF Aluminum Composite Panel

1500*5850mm 4mm PVDF Aluminum Composite Panel

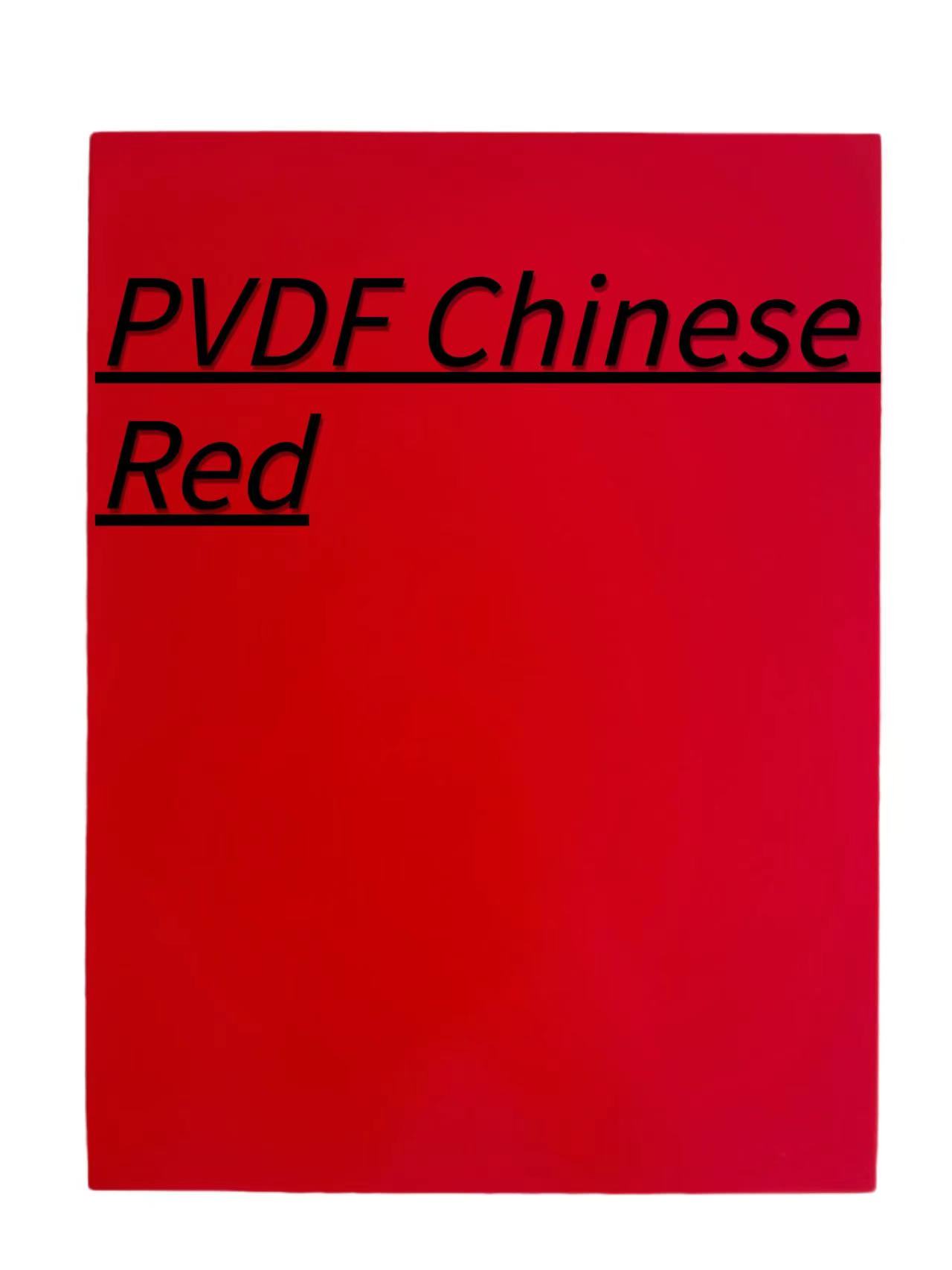

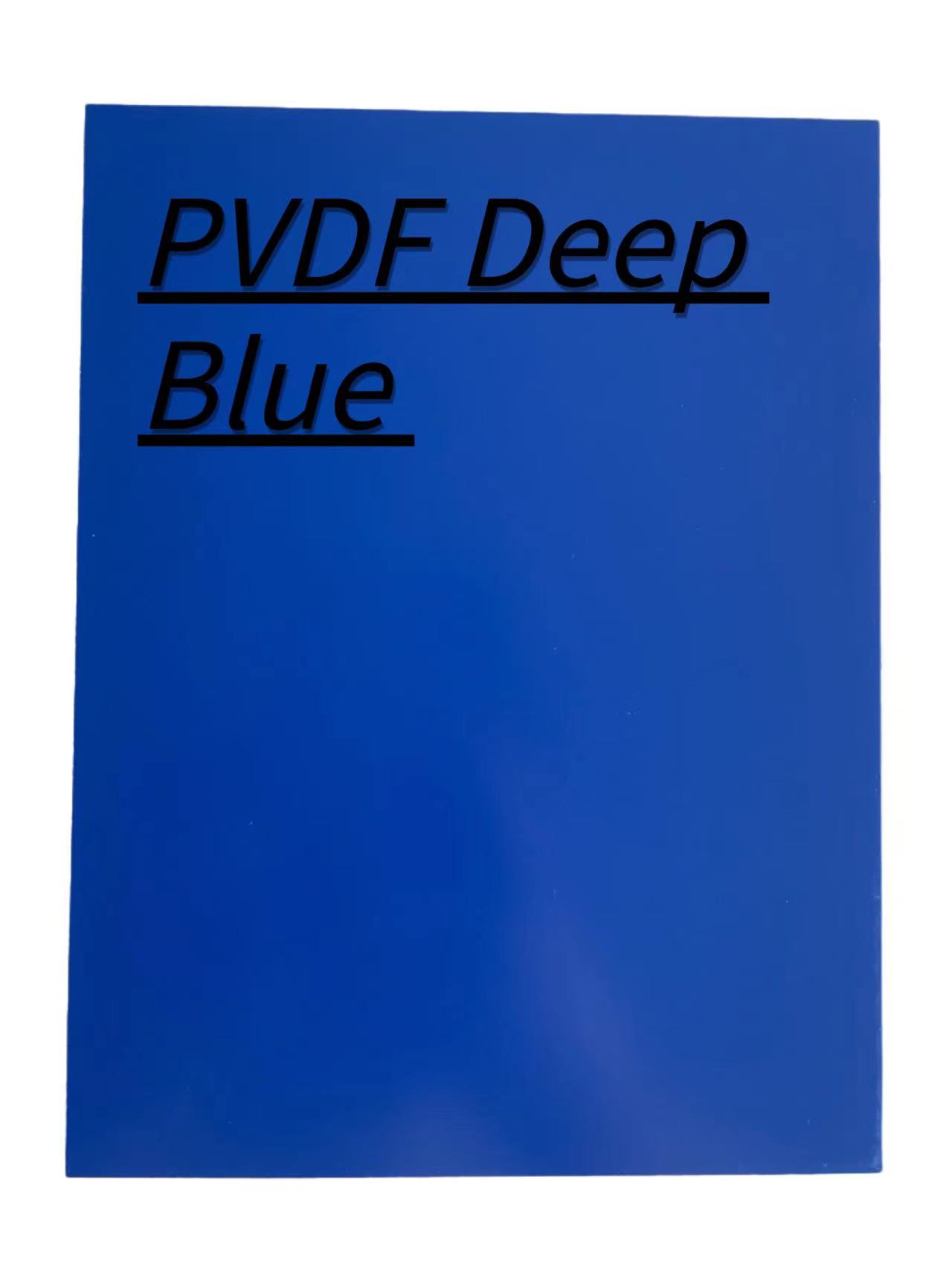

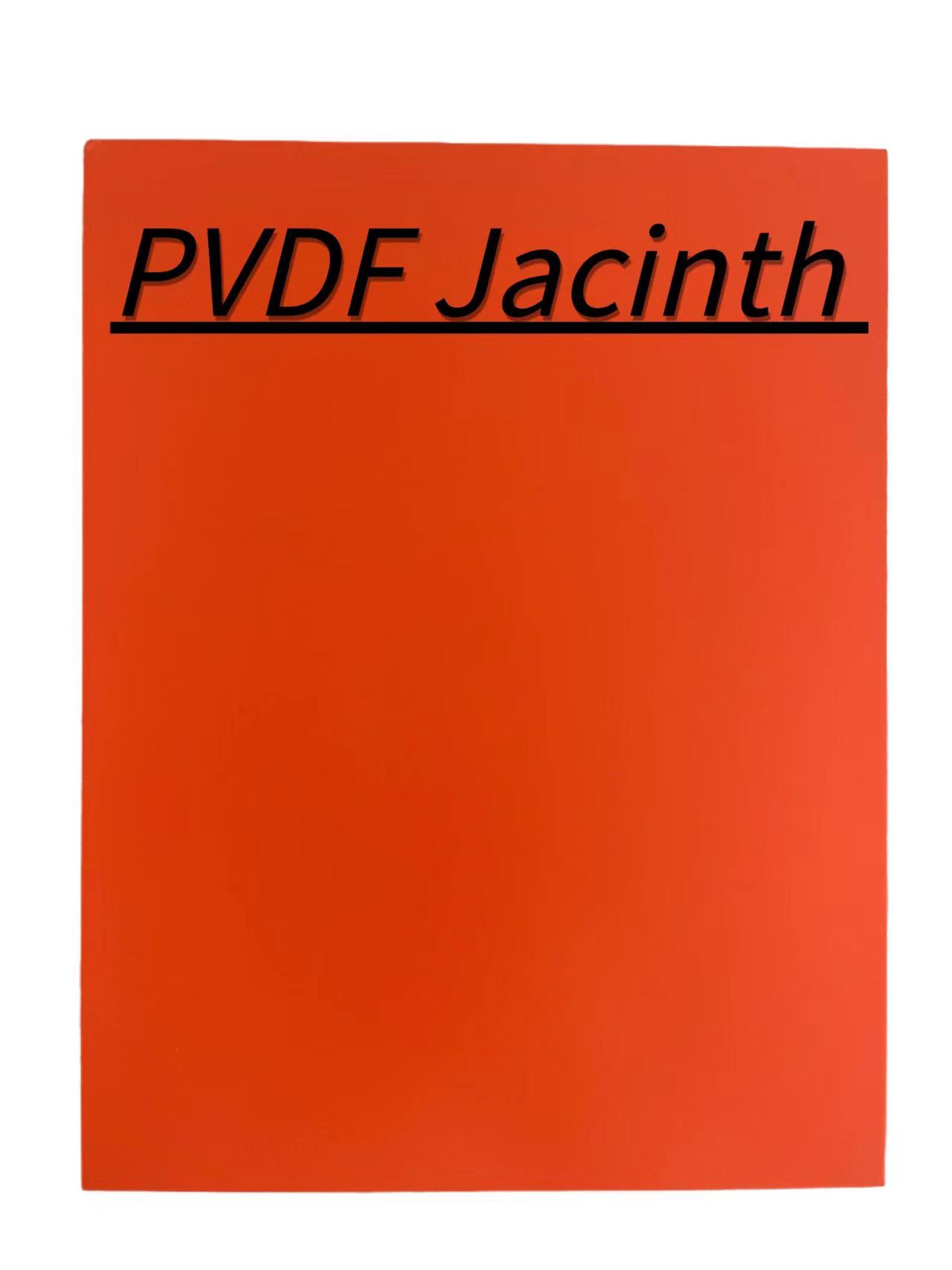

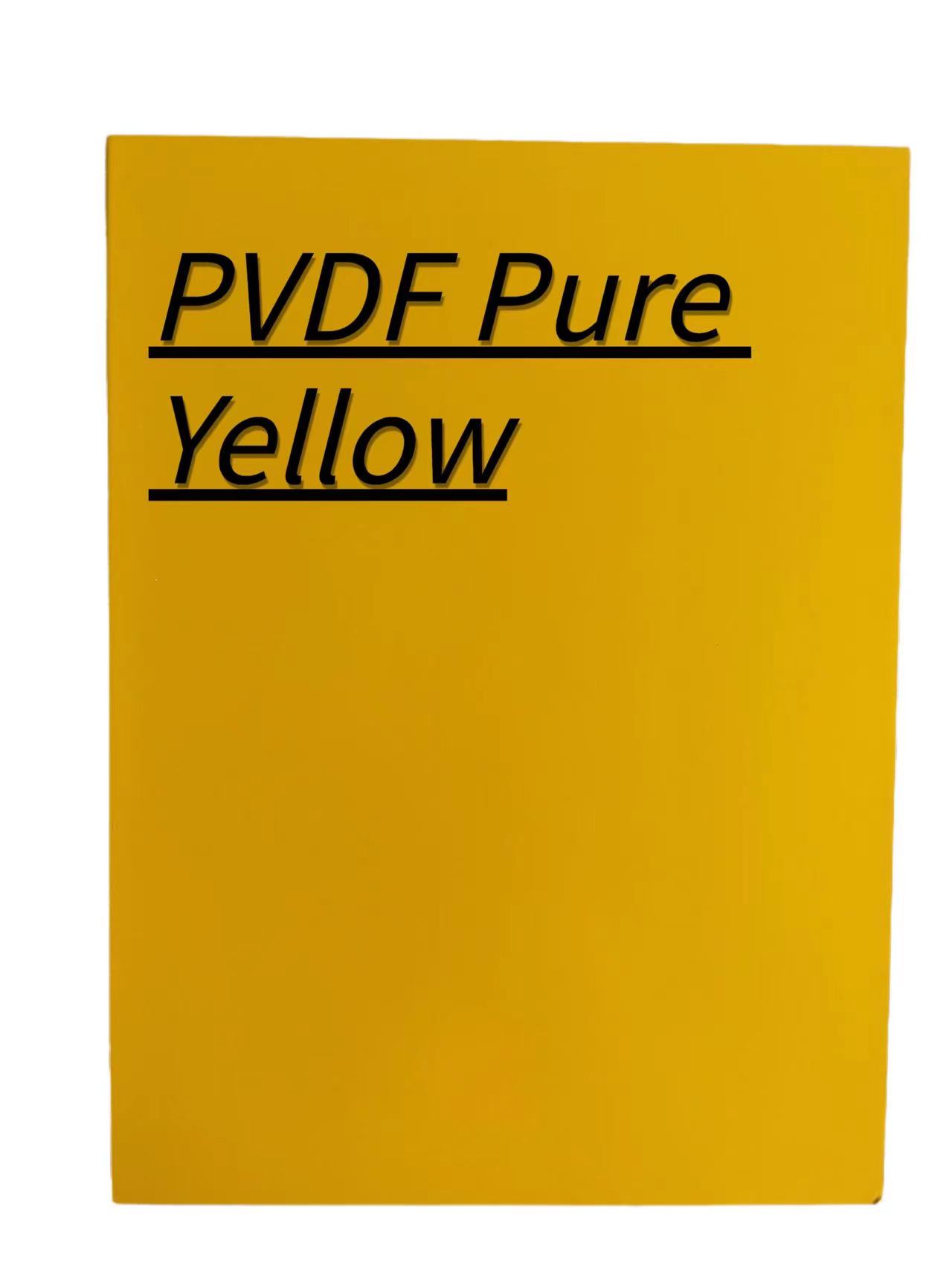

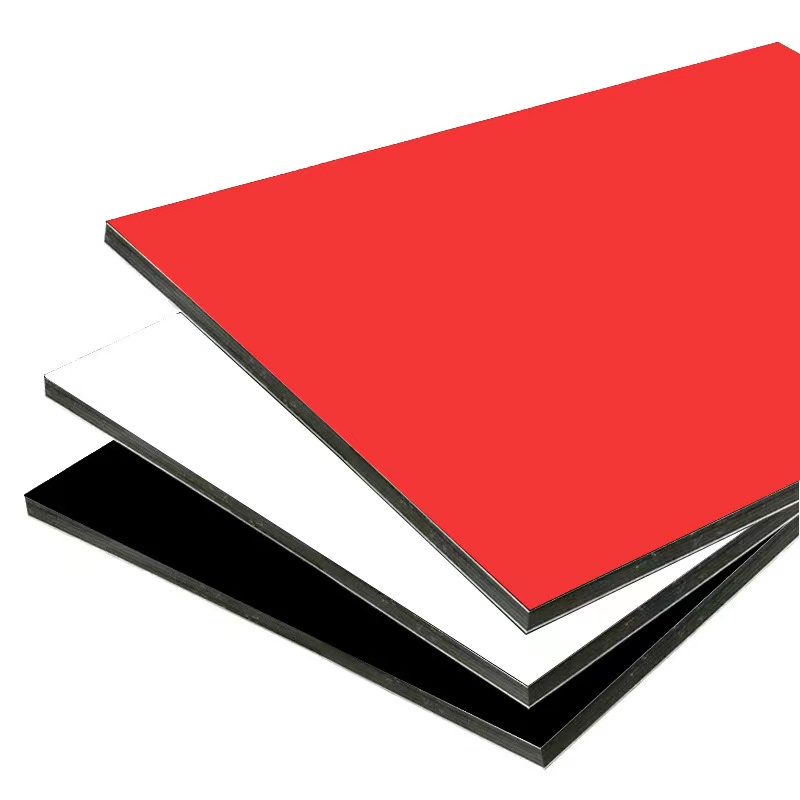

PVDF aluminum composite panels are produced by advanced equipment with German technique. It has two layers of anti-rust aluminum sheets, formed by low density polythene (LDPE) and DUPONT adhesive polyolefin film with continuously high temperature and high press. The surface aluminum sheet has been coated with 70% PVDF (polyvinylidene fluoride). And the backside aluminum sheet has been protected with an anticorrosive primer coat. PVDF aluminum composite panel is applicable for exterior decoration of architectures and curtain wall decoration of major constructional projects that have high demand for weather resistance.

Product Specifications

Thickness: 2-6mm; 3mm and 4mm is recommended

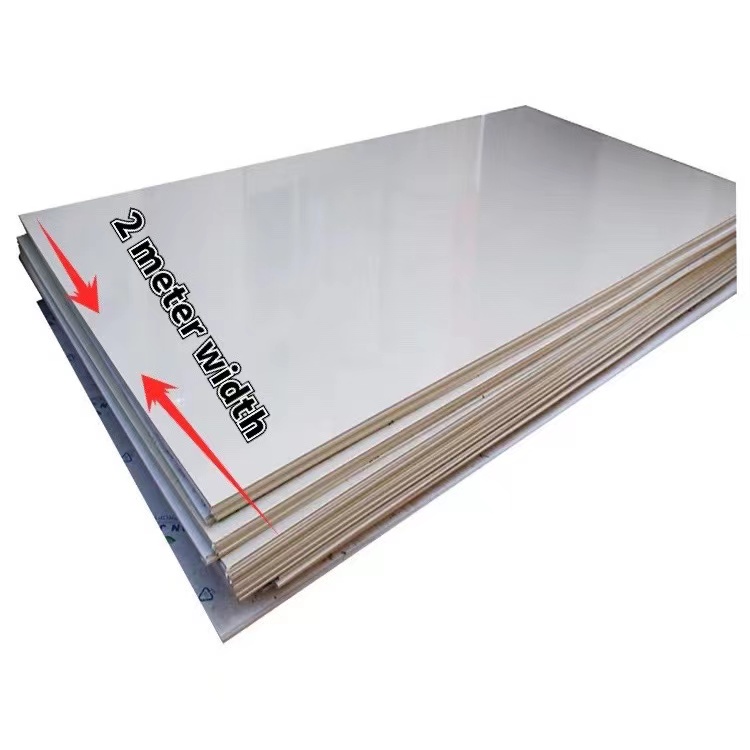

Width: 1000-2000mm; 1220mm, 1250mm and 1500mm are recommended

Length: Maximum can up to 5800mm, 2440mm,3000mm and 4000mm are recommended

Thickness of aluminum sheet: 0.21mm-0.5mm

Raw Material

Aluminum Material: High strength aluminum alloy sheet

Core Material: Non-toxic low-density polyethylene

Surface Coating: PVDF coating

Bottom Coating: Anticorrosive primer coating